This post reads more like rapid bullet points than a story. I tried to keep this short while still mentioning the important parts. I also have been reading way less than I used to, so my writing sucks a bit now.

Some quick numbers:

Final sold V5 box count: 69 boxes // (28% increase)

Delivered 91 pounds from coffee club boxes) // (30% increase)

34 return buyers // (21% increase)

Things that went well:

Still in growth phase:

We are still growing. I was nervous I would plateau after V4, but fortunately, that didn't happen. 🥲 The three metrics I'm tracking are still pointing upward.

The above graph is a split of new/return customers. What I take away from this is I need to focus on bringing in new customers as I feel that the number of "new customers" (per coffee box) should be higher than "old customers."

I interpret the upward trend of returning customers that the product/brand is strong enough to have people stick with us and continue staying a customer (pray thank you).

Action Items:

It’s time to up packaging, marketing, and maybe try advertising.

Do more in-person events.

Put more effort for wholesale as cafes may be able to help increase awareness about our project

Move to Multimodal:

Moving my operations to Multimodal, a shared roastery, helped with scale.

I now roast on a Diedrich IR-5, a 5kg drum roaster, which means I don't have to spend 20+ hours roasting. For V5, I spent around 8 hours production roasting.

Being at Multimodal also helped reduce packing time. They have a bag sealer that runs with a moving belt. You fit the bag horizontally, then the belt moves the bag through the sealer and seals it.

No more pressing down on a lever three times, then flipping the bag around, and pressing the lever another three times. No more needing to take a break from sealing because the smell of burnt plastic got too strong. 🥲

Shipping boxes:

Putting together the V5 boxes was much more enjoyable compared to V4. I went with foldable mailers, and that was the right move. Having it as a mailer allowed me to assemble the boxes with minimal tape. This significantly improved my workflow and removed the worry I used to have about whether the taped box would hold or not. These mailers were designed not to need adhesives.

Reddit Post:

It's a small win here, but seeing compliments on my Reddit post was humbling.

From a business standpoint, these comments provided credibility and suggested that I wasn't selling a scam. From a personal standpoint, seeing some validation from my community (r/williamsburg) felt nice. <3

Things that didn't go well:

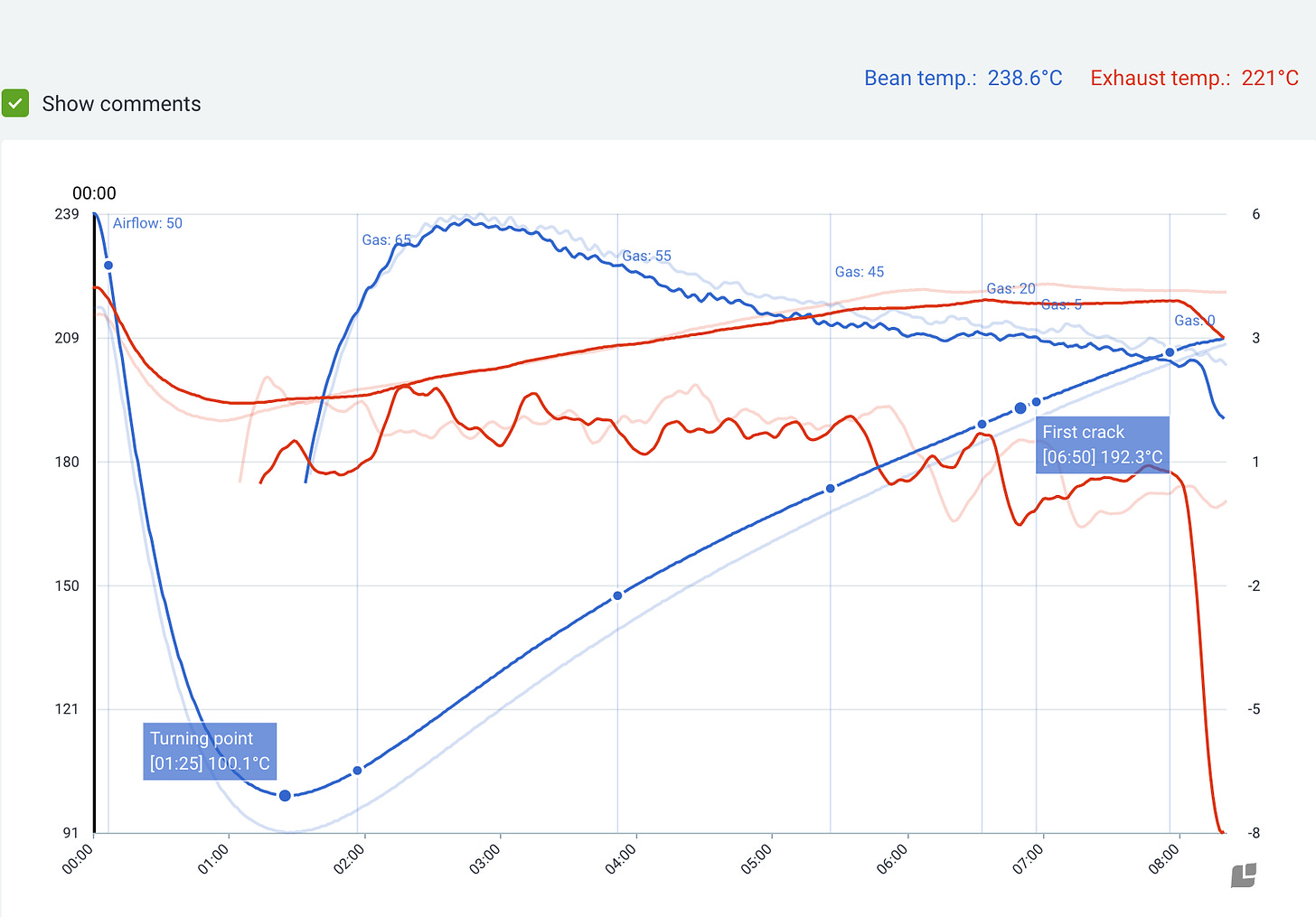

Roasting on the IR-5:

It was like learning a new roaster all over again.

To preface, the roaster I've been using for prior versions was the Aillio Bullet. The Bullet is a home 1kg electric drum roaster.

The new roaster I moved onto was the Diedrich IR-5. This machine is a gas drum roaster.

There is probably a laundry list of differences between the two machines, but I'll limit it to two.

1. Roasting Workflow Differences

The Bullet logged data automatically. Whenever I made a change on my laptop, it tracked it automatically. When you wanted the roaster to be at a specific temperature, all you had to do was set a value in the software, and the controls of the Bullet would get you there.

The workflow with the IR-5 was much more manual. The coupling between the software and the machine was less tight than the Bullet. You couldn't directly control the roaster's mechanics from the software. So, it was like a one-way data flow: the roaster could output data to the software, but it could not take in input (i.e., instructions) from the software.

Workflow:

You'd hit the start roast button on the computer to start tracking time

Then go to the roaster and drop the beans into the roaster

Then go back to the computer to log your initial settings

Then, for every change you wanted to make, you'd go back to the roaster, make the changes, and then go back to the computer to log what you changed

Iterate

There's more cognitive overhead with the IR-5, which isn't horrible, but it's a bit more error-prone.

2. My temp calibrations/roast durations were pretty off.

For the Bullet, I charged the machine at around 290C-300C for a 730g batch. Working with charge temps around this range was normal and made sense.

For the IR-5, it was suggested to charge anywhere from 180C to 200C. This temperature was way lower than what I was used to, so all the heuristics I built up about how temperature would behave no longer applied. For the first few roasts, I applied patterns I observed from the Bullet with the IR-5, and what resulted were scorched roasts.

Logistics at Multimodal:

1. Look into using their packing machine

Packing got better this time around (see above), but it was still very painful. I think I spent 8-10 hours weighting beans.

I might have packed 25% of the orders at Multimodal. I had to take the rest home and pack since I couldn't finish before they closed. This was where the pain started happening.

At home, the flow was to weigh the beans, then walk to heat seal the bag (reference above lever pressing for details), and then repeat. Doing this for 150+ bags was exhausting.

So yeah, in the future, I will try to do all my packing at Multimodal using all of their commercial-level packing tools.

That was exhausting.

Action Items:

Do all my packing at Multimodal

2. Up roaster batch size:

The batch size I chose to start was 4 lbs. I thought choosing something small for my first sessions would help lower the risk; it did, but it also meant that I had to run more roasts.

What I forgot was that I didn't have unlimited roast time. I was paying by the hour, so if I didn't roast enough at the end of my session, I had to buy more time. This was the reason why my "roasting cost" costed so much for this coffee club.

Action Items:

Up to 7.5lb batches. I've received feedback from multiple roasters that this batch size is optimal for this roaster.

Plan better, and give myself more of a buffer when figuring out how many batches I can run in a session.

Communications:

1. Need more automation:

The scale of individual emails I'm sending out now is getting unmanageable. This wasn't a big issue in earlier versions as managing 12-20 email recipients was doable. But now with 69 recipients buying at different stages (presale vs regular), emails are getting a bit messy. In V5, we had our first error.

I accidentally emailed people with shipping orders about in-person pickup scheduling. This mishap caused some confusion and panic.

Action Items:

Look into automation that could help us schedule emails after purchase, collect responses, and periodically follow up if the responder doesn't respond.

2. Require phone numbers:

Apparently, my email is going into spam (separate issue...). Moving forward, I will require a phone number before placing an order.

A few buyers had all my emails go into their spam folder, which resulted in them not responding. This induced stress on my side since I wasn't sure how to proceed.

Action Items:

Require phone number in Shopify profile before ordering

Add in a note that if I don't hear from you within X days, I'm going to text you.

Thank You's:

Shaina + Carli (from The Libi Project):

The community that you are both creating is amazing. I've always been fascinated with the culinary industry, and your project has helped bring my project closer to that field. Thank you for including thoughtfulcoffee in your thoughts.

I've only met you in person once, but you immediately started sharing my coffee with others, advocating and thinking of opportunities for me. Thank you!

I’ve just met you, but you immediately started thinking about potential collaborations for me and making introductions. Thank you!

Thank you for all your work! You've both put in a lot, and I really appreciate it. I can't wait to see and share the results of your work. Everyone else should be excited too!

@maxwheel / John Pang / Anton + Paolo (from Multimodal):

Thank you all for providing tips on roasting on the IR-5. I couldn’t find a lot of information on how to roast with this machine, so all your advice were immensely helpful. I look forward to continue learning from you all.

Ethan (from Multimodal):

Thank you for always accommodating me on the many Sundays I had to drop in. Sorry for having you turn the heat sealer back on when you were close to closing. 🥲

Matt (from City Boy Coffee):

Thank you for taking the time to answer all of my questions about Multimodal! Your answers were super helpful, and ultimately convinced me that I was making the right decision moving to Multimodal.