Roast #13: Reflection on V2

Reflectionagainagainagainagainagain

I hope everyone is having a great holiday season right now.

Like last time, I'm going to write about what went well and what didn't with coffee club V2.

This round took one month less than the last coffee club round. Yay for improving!

Things that went well:

Better Beans:

The quality of the beans was better this time around. I was able to better nail down my coffee green buying process. With V2, I sampled over 20 different types of coffee and picked my favorite three. Of the samples, I had a good variety of regions, types of processing, and fermentation methods.

You can read more about how I chose the beans here

But anyways, my point here is that V2 was my intro to applying more processes to my coffee green buying process and going more upstream in coffee green quality.

Better Roasting:

My roasting got better. I had a better idea of why I was making adjustments and started building out my own fundamentals.

You can read more about my thoughts on this box’s roasts here

My roasting process with each bean was to:

1. Do some research to see how others roasted this bean and to note when certain key events were happening.

2. Plan multiple roasting profiles to try out, with each targeting a variable tweak

3. Execute the planned roasts!

4. Rest the beans

5. Cup and figure out which was my favorite roast

6. Let the roast rest for 3-7 days -- while intermittently brewing in between

7. Determine if we can get a brew that I like and am happy with. If so, then lock this bean in for the coffee box.

8. Then scale the roast!

Brewing doc:

I got to get deeper into the coffee by figuring out a brew guide for each coffee. Going through this process not only helped me continue QAing the beans, but I also learned what methods could work better for certain types of coffees.

You can read my brewing notes here.

As I do more boxes and build more of these guides, I'll start to figure out brewing rules that I can softly apply on coffees depending on their processing/fermentation style. For future brewing guides, I'll try to consider more different variables like grind size and brew temperature.

The pretty cards:

The coffee cards came out amazing. I originally wasn't planning on including any cards as I wanted to go with a full-on "anti-design/marketing" look, but after building out an initial test box, the brown bag in the brown box felt somewhat lacking. And I didn't want to underdeliver compared to the first version, so I asked her to help come up with a last-minute design. And she came through. So major thank you to Jasmin for helping me come up with a fantastic design so last minute.

Things that didn’t go as planned:

Drop off in payment:

Not everyone who expressed interest in V2 followed through. Some of the drop-offs were likely due to a loss of interest from signing up months before the product delivery. Most drop-offs came from people who signed up close to the delivery date but never completed payment. I think people thought this project could've been a scam because I asked for payment through my personal Venmo account. But I could be wrong.

Hopefully, this won't be an issue as, moving forward, I'll be using a business-specific Venmo profile to take in payments.

Marketing is hard:

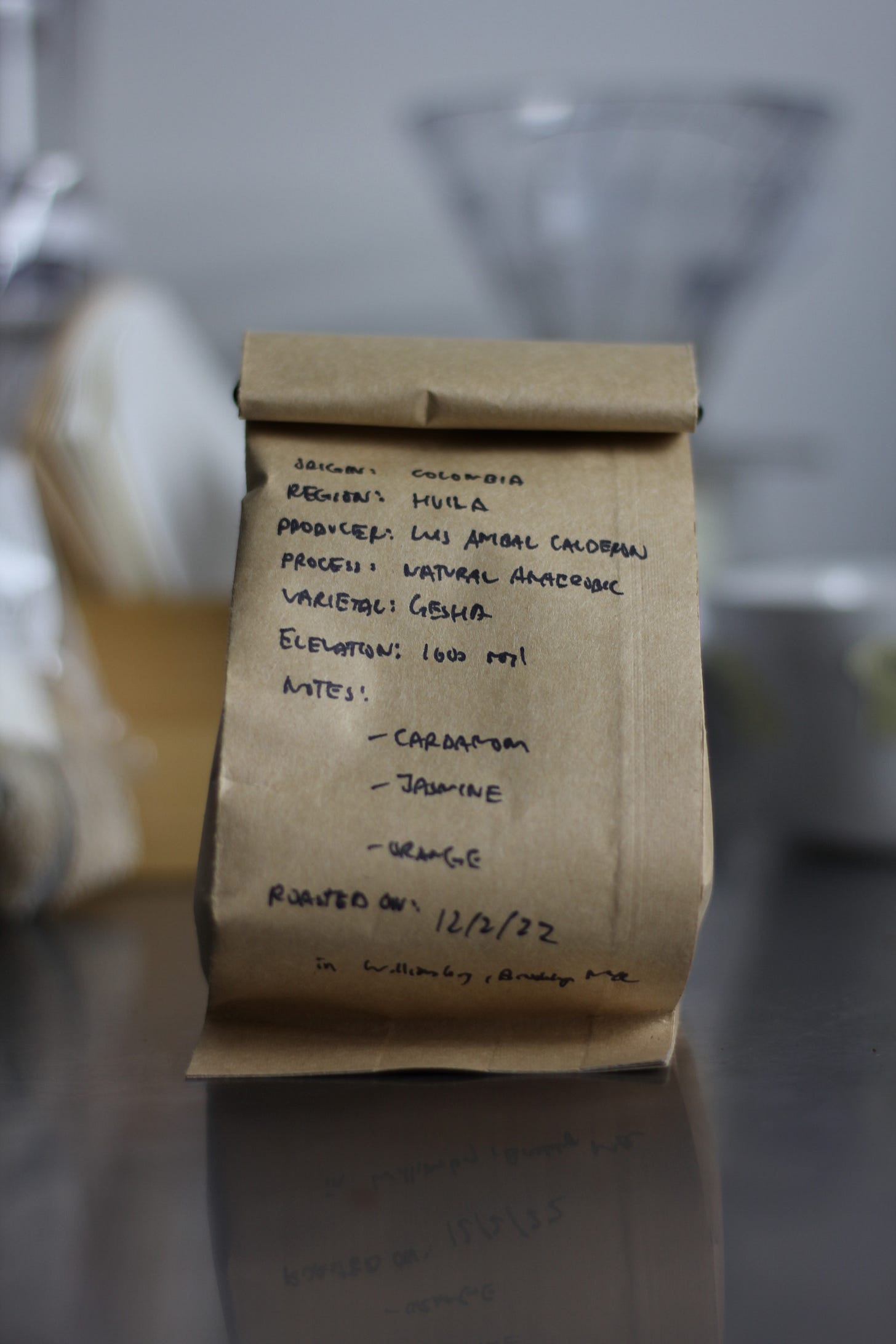

Marketing is hard, and I need to learn how to increase my digital reach. I have no interest in building a vast coffee empire or making millions of dollars, but I want to expand my reach to buy more tools to improve the quality of these coffees. Right now, the only avenues I'm promoting my project are Reddit, Instagram, and this blog. Another avenue I'll start exploring more is in-person events. I applied to vend at two holiday markets this winter but was rejected for both. I think the rejections were due to the small size of followers on my Instagram and the lack of professional product branding (handwritten labels).

No upgrades before roasting:

Although the overall roasting process improved, there were still some rocky parts. The first was that my roaster's software bugged out after a software update. As a result, the roaster was stuck in a limbo state where I'd plug in the roaster, and only the exhaust fan would run. This incident happened on the Monday of the launch week. Fortunately, their support was responsive and was able to help me get everything fixed a day later. But a lesson learned: Don't do major software upgrades before a large roasting session.

Still too manual and inefficient:

Building out the box is still manual. I thought scaling the roasts to 1lb increments would help decrease roasting time, and it did, but I didn't account for the fact that an increase in orders would also need more time. With each coffee bag needing 120g, I was able to fill three bags per every 1lb roast after accounting for weight loss. Each roast took 20 minutes: 10 minutes roasting, 5 minutes QAing/bagging, and another 5 minutes pre-heating. So per hour, I could fulfill nine bags of coffee, or three coffee boxes, which isn't too efficient.

I'll need to scale the roasts to a higher increment -- maybe 1.5 pounds. The maximum capacity my roaster can roast is 2 pounds, but it's ill-advised to roast at that quantity. If I get to the point where I'm roasting 50+ boxes, I'll likely have to look into a larger roaster.

Then there was the issue of having to write out the labels. Other than the production roasting, writing labels was what took up the most amount of time. I had to spread the work out because my hand would start hurting after doing this for a few hours.

Behind the scenes:

If you were interested in some behind the scene videos for this box, head over to my Instagram to view the behind the scene post.

Thanks for reading!